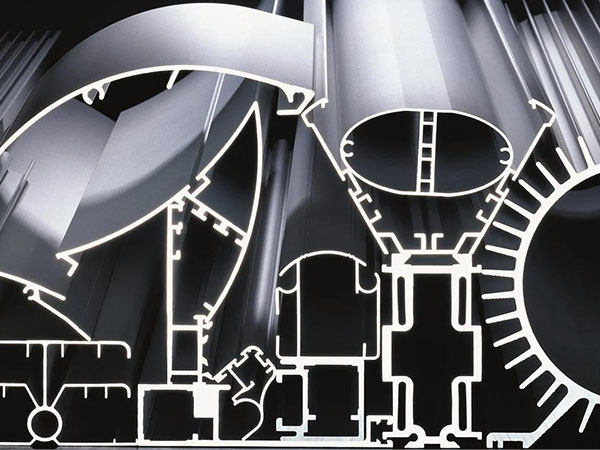

You can choose our products .Also we can OEM for you customized products. Please send me your drawing Material requirments and surfacetreatment. ECT all kinds of requirment. Our engineer team will service for you for all series technical and products issues. Toppest technology. Best Service and Best price with quality. Fine Aluminum best choice for you.

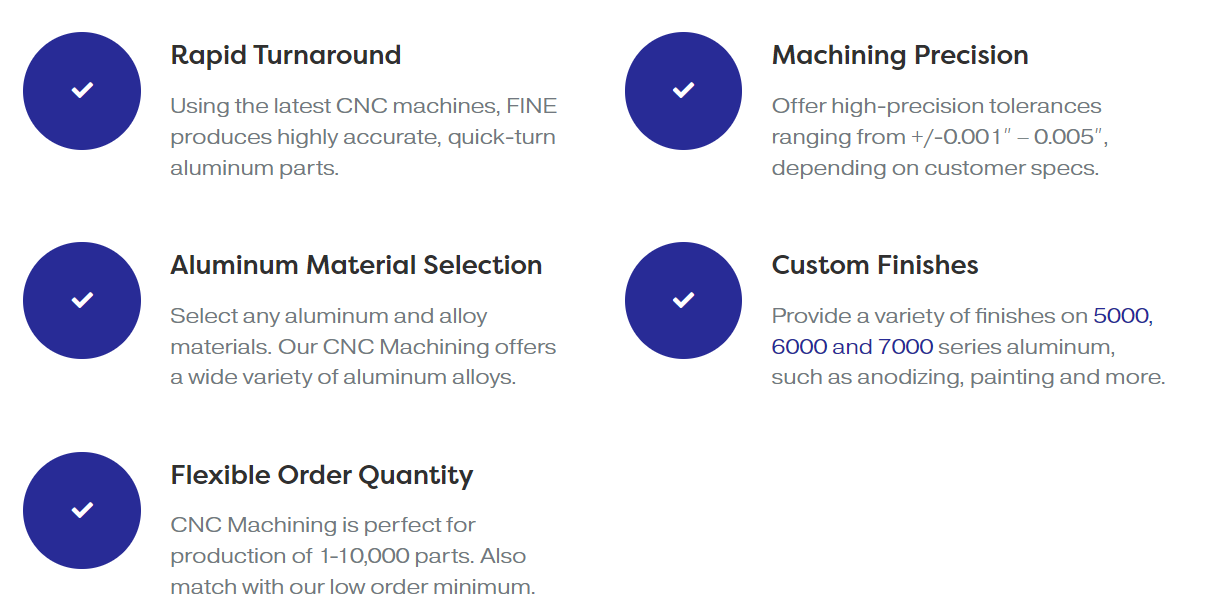

Benefit You can Find in Fine

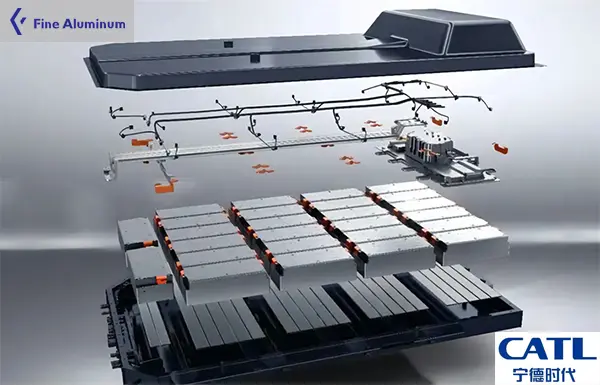

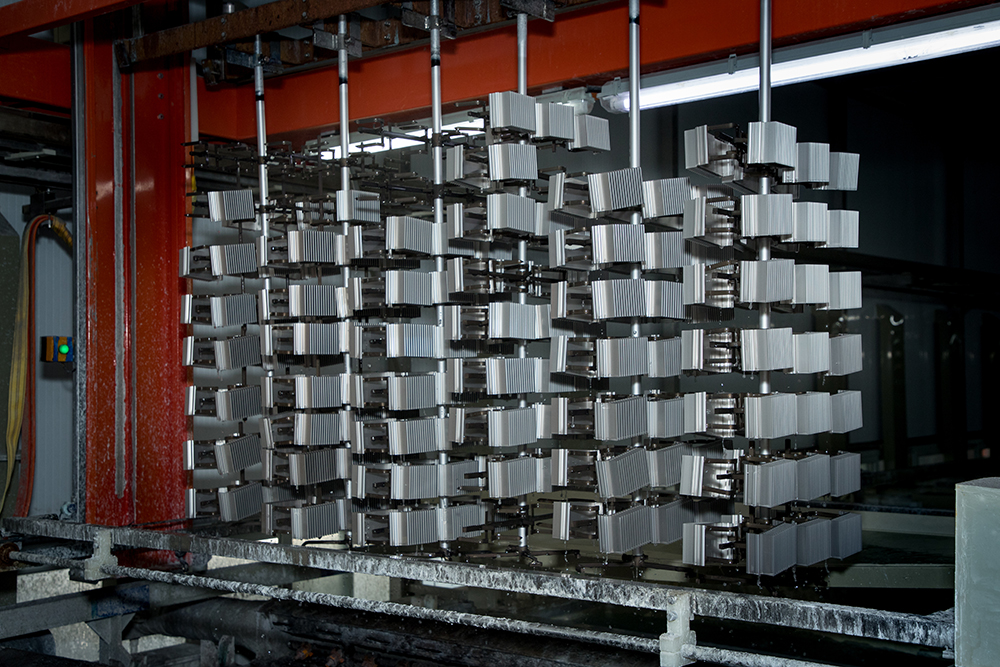

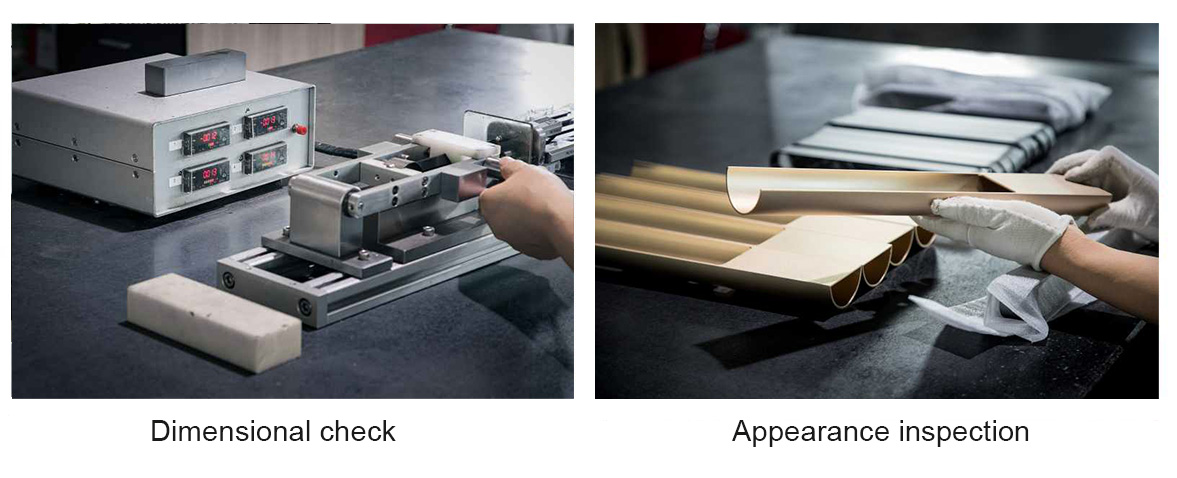

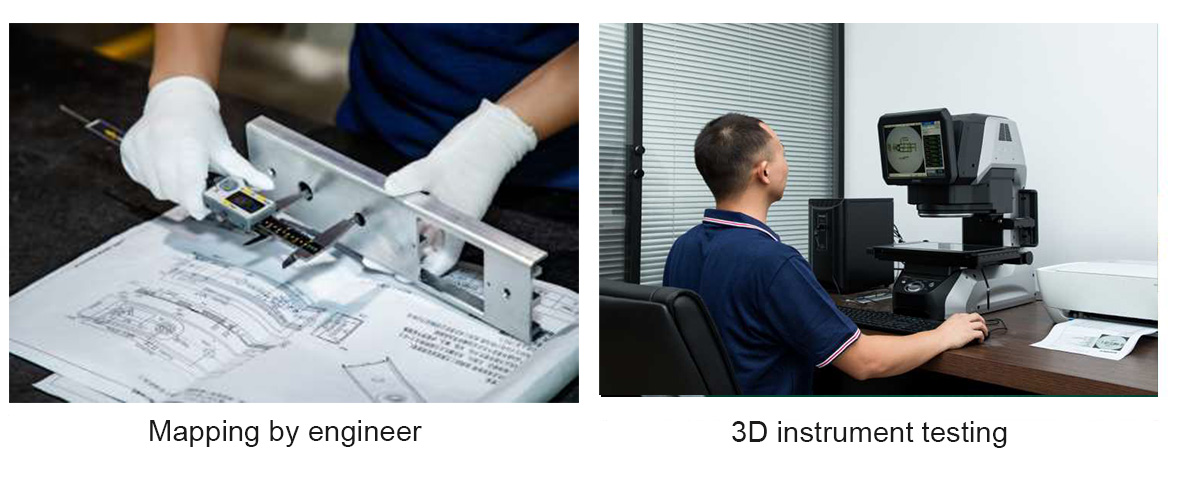

We develope and manufacture a variety of aluminum heat sinks used in applications including power modules, electronics devices and many other cooling systems. Whether you are looking for quality manufacturing on your custom designed aluminum heatsinks, or seeking early assistance in heatsink design, feel free to email us at shenbing@fnmetal.com. Our team of engineers, toolmakers, machinists and sales support staff are here to help.

We're here to help with

- FREE CAD/CAM design support

- Manufacturing programs

- Real-time production tracking

- Product troubleshooting and diagnostic assistance